5 March 2012

BAGGAGE COMPARTMENT

The baggage floor was debur. Three L angles each with 260mm long were cut.

A center line was drawn on one flange and first rivet location at 10mm from the end are marked.

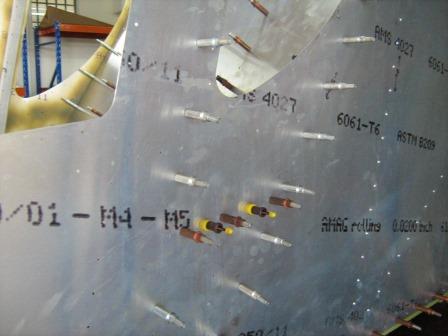

With a #40 drill bit, the holes are back drilled in the baggage floor into the L angles and clecoed.

With #30 drill bits, the holes were expanded and clecoed.

The baggage floor was positioned. Then, the baggage floor was clecoed

to the side skin and the baggage back.With a #30 drill bit, the holes

were expanded through the baggage floor into the

baggage back and the both side skin and clecoed.

The right baggage upright (75F5-4) and left baggage upright (75F5-5) were then debured.

Both parts were then clecoed to the baggage floor and the side skin.

With a #40 drill bit, three holes were then back drilled on the baggage

upright into the flaperon control cover and clecoed, right and left side.

The torque tube bearing support (75F5-1) were clecoed to the torque tube bearing channel.

With a #20 drill bit, four holes were expanded through the torque

tube bearing support and the torque tube bearing channel.

The right control tunnel side (75F6-2) and left control tunnel side (75F6-3) were then debured.

The control tunnel top (75F6-4) also was debured.

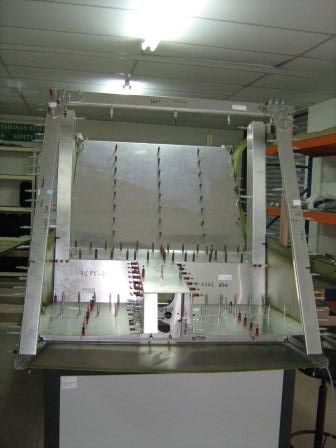

Both right and left control tunnel side was clecoed to the right and left baggage upright.

The control tunnel top also clecoed to the baggage uprights and tunnel side.

With a #30 drill bit, right control tunnel side pilots holes were

drilled through the right upright. Then, the left control tunnel side

was drilled through to the left upright.

With a #30 drill bit, the holes was expanded through

the baggage floor to the right baggage upright,

control tunnel top and left baggage upright.

The right lower baggage floor (75F5-6) and left lower baggage floor (75F6-1) were debured.

Two L angles each 270mm long and two L angles each 240mm long were then cut.

The center line was drawn on one flange and first rivet location at 6mm from the end.

With a #40 drill bit, the first hole on the mark was predrilled.

The L angles were clecoed to the lower baggage floor and the L angles

was rotated until the center line visible through the predrilled holes.

With a #40 drill bit, the holes in the lower baggage floor were back drilled

to the L angles and clecoed. The rear L angle was checked

overlapped with the torque tube bearing channel.

The right and left baggage floor were clecoed to the torque tube bearing channel,

right and left control tunnel side, right and left baggage uprights and side skin.