6 March 2012

BAGGAGE COMPARTMENT

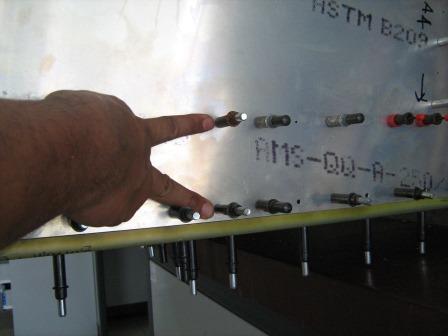

With a #30 drill bit, the holes on the baggage floor (right) was expanded through the L angle.

The same procedure was applied to the left baggage floor through the L angle.

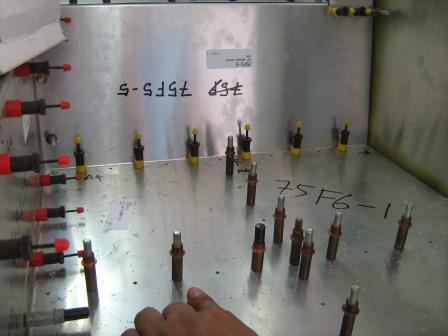

With a #30 drill bit, the holes was expanded on the right baggage floor through the right upright (75F5-4)

The above procedure was also done to the left baggage floor through the left upright (75F5-5)

Three holes was expanded to A3 size rivet hole on the right upright through the flaperon cover (right)

Three holes was expanded to A3 size rivet hole on the left upright through the flaperon cover (left)

With a #30 drill bit, the holes was expanded on the right baggage floor through the torque tube bearing channel.

With a #30 drill bit, the holes was expanded on the left baggage floor through the torque tube bearing channel.

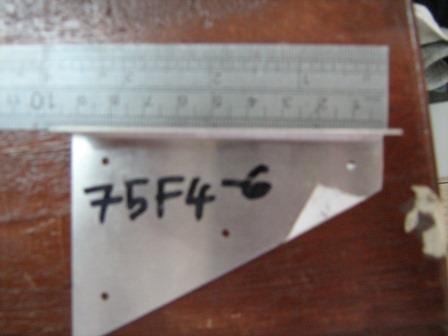

The left gusset was trimmed 2mm from the tap edge because the edge was clashed with

the baggage floor and as a result, the pilot holes of the gusset were not aligned with the side skin holes.

After trimmed, the holes was matched. The trimmed gusset was still agree with the construction standard.

The right gusset was positioned on the right side of the torque tube bearing channel.

Then, with a #40 drill bit, the gusset was then drilled through the torque tube bearing channel.

Then, with a #30 drill bit, the holes were then enlarged.

The left gusset was positioned on the left side of the torque tube bearing channel.

Then, with a #40 size drill bit, the gusset was then drilled through

the torque tube bearing channel. Then, with a #30 drill bit,

the holes was enlarged.

The #30 drill bit was used to enlarged the top hole of the gusset to the right side skin.

With a #30 size drill bit, the top hole of the gusset was drilled

to the left side skin. The bottom hole of the gusset was drilled

to the left side skin with a #20 size drill bit.

The right upright and the right side skin holes were then enlarged to #30 size hole.

The left upright and the left side skin holes were then enlarged to the #30 size hole.

The baggage back and the baggage back angle was taken out from the assembly.

After measurement was made to the baggage angle (using the left over longeron)

straight lines was made to assist to locate holes location with the predrilled holes on

top of the baggage angle. The baggage angle were then clamped to the top of baggage back.

When the lines was line up with the predrilled holes, with a #40 drill bit, the holes were drilled

to the baggage back and the baggage angle. Then, the holes were then enlarged to a #30 size holes.