2 February 2011

RUDDER ASSEMBLY ( CONTINUE)

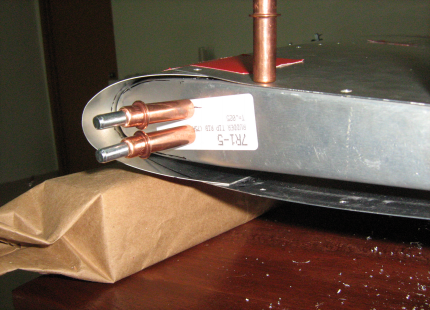

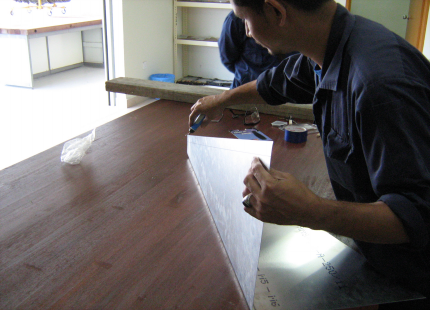

The side flanges were clamped to the Skin to keep the Nose Rib in position. The Rudder was positioned correctly on the boards or beams with spacer under the bottom trailing edge. The drilling process was initiated from Nose Rib working toward each end and clecoed every hole on both sides.

The overhang was traced as close as possible and the remaining Skin was trimmed.

The Leading Edge Skin was clecoed.The Layout line was made about 10mm from the center of the rivet.

The excess material was trimmed off from the Nose Skin. This was finished by filling to straight smooth line.