26 May 2011

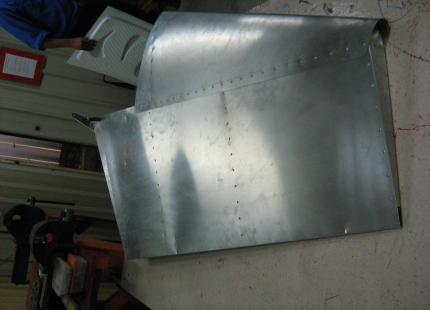

RUDDER RIVETING PROCESS

Mr Mutalib gave a brief description about riveting process

Reassemble and unclecoed of the Rudder parts

Deburred the holes at every holes

Drilling process to expand the holes to #30

After drilling process, clecoed with #30 Cleco

Applied alodine to every sheet metal part to protect the internal aluminium from corrosion

Riveting process

The Rib and Spar were riveted

Riveted the Spar and the Rudder skin

The final process of riveting

Primer the Rudder skin with base colour