4 October 2012

FUSELAGE JOINING & FORWARD FUSELAGE SECTION

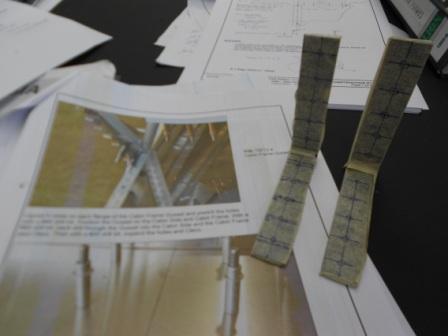

As in the photo manual and the plan, both called for 5 rivets on each flange of the Cabin Frame Gusset. So, we have layout five rivets on both flange of the Cabin Frame Gusset. The layouts are which 10 mm from the edge that is more than the minimum distance for an A5 hole that is 6 mm from the edge to the centre of the hole. And 13.5 mm from the bent or the flange that is 7.8 mm more than the minimum distance for an A5 hole that is 5.2 mm.

Both will be pre drilled with #40 drill bit and will be enlarged to #20 for final size.

We then clamped one of the flange of the Cabin Frame Gusset and other line is marked on the back of the flange on both flange to ease the drilling for the #40 drill size.

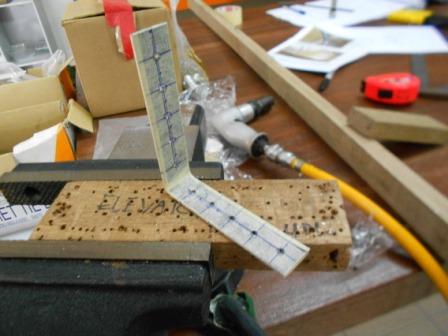

With a #40 drill bit, we then drilled the Cabin Frame Gusset. The part is clamped with G-clamp and drilling is made on top of a drilling wood.

Shown in the picture, one of the Cabin Frame Gusset was finished drilled with #40 drill bit.

And in the picture, this is the other Cabin Frame that was finished drilling with #40 drill bit.

We then positioned the Cabin Frame Gusset on the Pilot Side Cabin Side. We then clamped both flanges so that the flange is fixed and is positioned correctly to the cabin frame and cabin side. We also checked that the 95 mm flange is on the cabin side while the 90 mm flange is resting on the Cabin Frame. The cabin side that has been drilled yesterday has been deburred before the Gusset is positioned in place so that there is no gap or space between both parts.

The Cabin frame is gripped pin with #20 grip pin with the cabin side so that it is totally fit with the cabin frame. With Digital protractor, we also measure the angle of the cabin frame and the bottom of the fuselage, and no issue about that as the angle are the same on both sides.

With #40 drill bit, carefully we drilled through the Gusset into the Cabin Side and the Cabin Frame and gripped pin with #40 Grip Pin as shown. We used angle drill to drill the inner of the flange as the space is tight. But most of the part we have used normal air drill.

Here is another of view for previous operation.

- Hits: 130